Product Categories

Related products

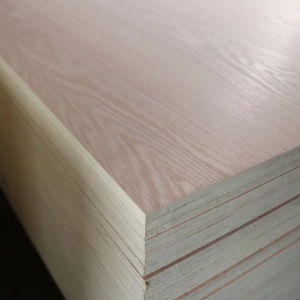

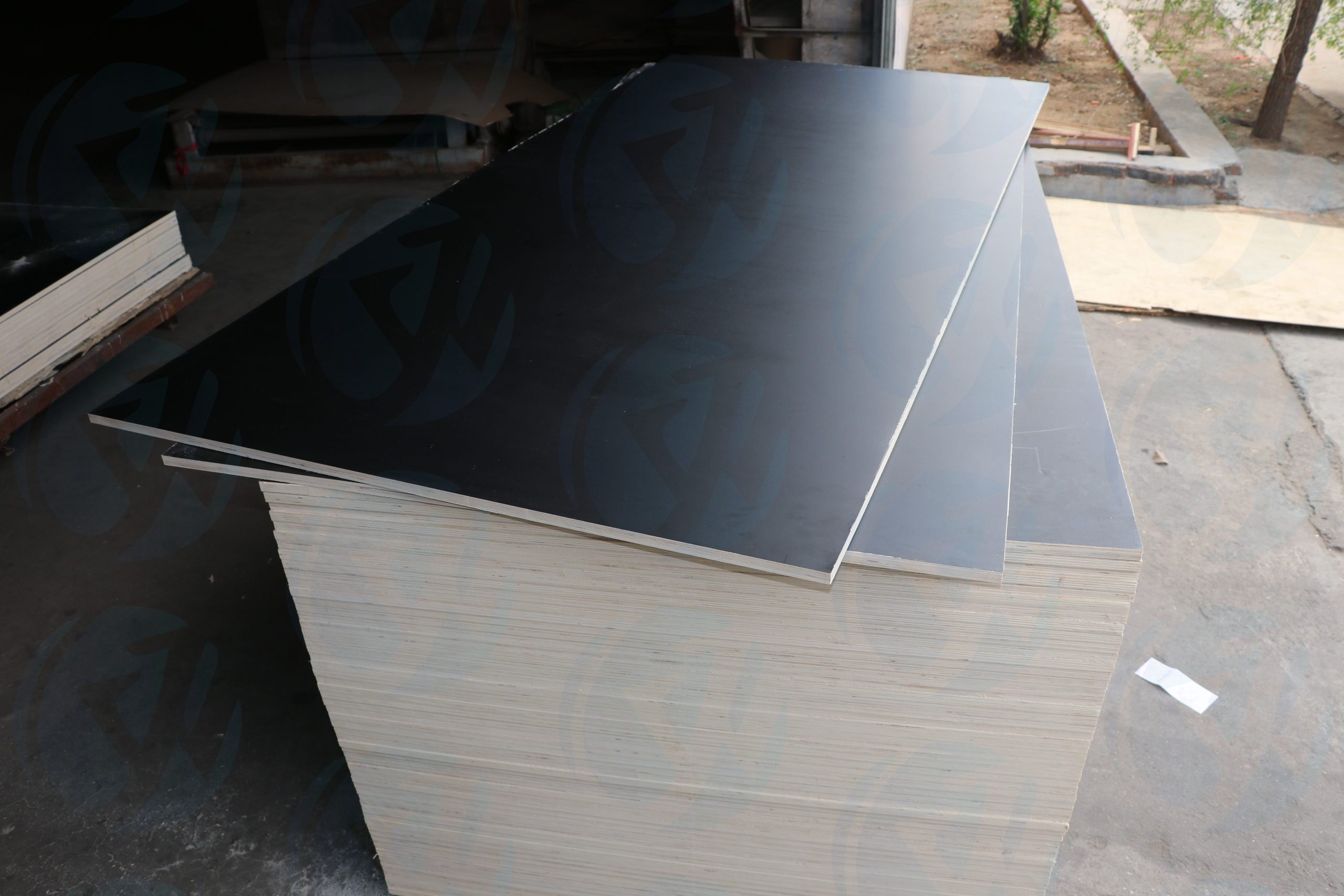

| Name | Film Faced Plywood |

| Size | 1220x2440mm,1250x2500mm,1200x2800mm,1200x3050mm 1525x3050mm ,610x2440mm, 625x2500mmor as Customized |

| Thickness | 2~30mm |

| Film | Black,Brown,Red,Green Plastic with customized logo |

| Core Material | Birch,Eucalyptus,Poplar,Combi core |

| Hot Press | 1 times,2 times |

| Glue | Phenolic,WBP |

| Usage time | 1-50 times |

| MOQ | 1*40HQ |

| Density | 550-700kg/m3 |

| Usage | construction cement form |

What is Film Faced Plywood ?

Film Faced Plywood is a high-strength plywood with a surface covered with waterproof and wear-resistant film, designed specifically for concrete pouring construction, and is one of the mainstream materials for construction formwork. Its core features are waterproof, corrosion-resistant, and reusable, widely used in construction projects.Film Faced Plywood has become the preferred choice for modern building templates due to its waterproofing, high strength, and reusability, especially for concrete projects that require a balance between cost and efficiency. Proper selection and maintenance can significantly improve construction quality and reduce losses.

Characteristic

1. Surface film coating

Double sided coverage of phenolic resin film (Brown/Black/Green/Red Film), smooth and waterproof, with a smooth concrete surface after demolding.

The film is acid and alkali resistant, and UV resistant (suitable for outdoor construction).

2. Substrate structure

The core layer is made of hardwood (such as poplar, eucalyptus, pine) or composite wood, with multiple layers of cross bonding and high bending strength.

The adhesive is usually waterproof phenolic glue (WBP, compliant with EN 314-2 standard).

durability

Can be reused 10-30 times (ordinary wooden formwork only 2-5 times), significantly reducing construction costs.

| Film Faced Plywood vs Formwork | |||

| Characteristic | Film Faced Plywood | Ordinary wooden formwork | Steel formwork |

| durability | 10-30 times | 2-5 times | 100+times |

| cost | medium | low | tall |

| Concrete surface | smooth | Need for secondary processing | Smooth but easy to stick mold |

| Applicable scenarios | Small and medium-sized buildings, bridges | Temporary Works | Large repetitive structures |

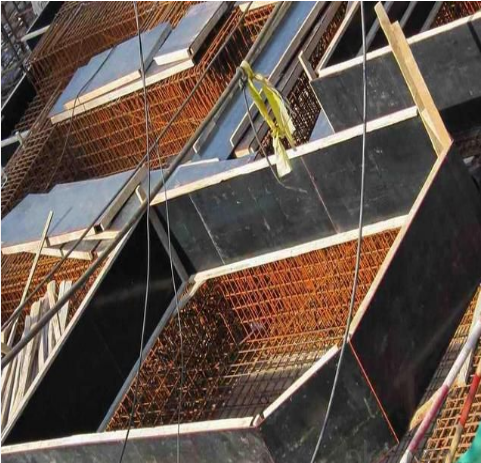

Usage

1. Concrete pouring construction

Wall/column formwork: supporting concrete shaping, easy demolding of laminated surface, reducing residue.

Floor/beam formwork: High strength load-bearing to avoid deformation during pouring.

Bridge/tunnel engineering: resistant to moisture and long-term loads, suitable for large-scale infrastructure construction.

2. Special building requirements

Clear faced concrete: Covering film provides a smooth surface, directly presenting decorative concrete effects.

Curved structure: Some laminated boards can be bent to accommodate irregular designs.

3. Other industrial uses

Temporary flooring/workbench: pressure resistant and moisture-proof, used for construction sites or factories.

Packaging box/container pad: high-strength moisture-proof, replacing ordinary plywood.

Purchase suggestions

Select level according to engineering requirements:

Ordinary engineering: 12-18mm, brown film, high cost-effectiveness.

High strength engineering: 18-21mm, black film, stronger weather resistance.

Quality inspection:

Observe whether the film coating is uniform without bubbles and the edges are not cracked.

The core layer has no voids and the layers are tightly stacked (listen for a dull sound when tapping).

FINGER JOINT /SKYPLEX

Glue: WBP Melamine

Thickness: 12/15/17mm

Reuse: 2-4 times

Price: Medium

Finger joint core film faced plywood consists of small wood pieces seamlessly connected using interlocking finger joints.This design enhances strength, stability, and resistance to warping or splitting. Finger joint cores are ideal for applications demanding superior structural integrity, such as construction, flooring, and furniture manufacturing.

|

COMBI CORE/CHANTAPLEX

Glue: WBP Melamine

Thickness: 12/15/18mm

Reuse: 10-15 times

Price: Medium

Combi core film faced plywood is made from the lightweight and straight-grained poplar wood. It is known for its stability, ease of use, and affordability.Combi core plywood is commonly used in interior applications like cabinetry, paneling, and decorative projects where weight and cost are important factors.

|

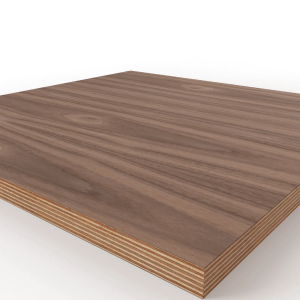

FULL BIRCH CORE

Glue:WBP Melamine

Thickness: 12/15/18mm

Reuse: 20-30 times

Price: Premium

Full birch core film faced plywood is derived from the fast-growing eucalyptus tree, known for its strength and durability.It provides excellent stability, resistance to moisture, and high load-bearing capacity.Full brich core plywood is often used in outdoor and marine applications, including boat building, exterior construction, and infrastructure projects.

|

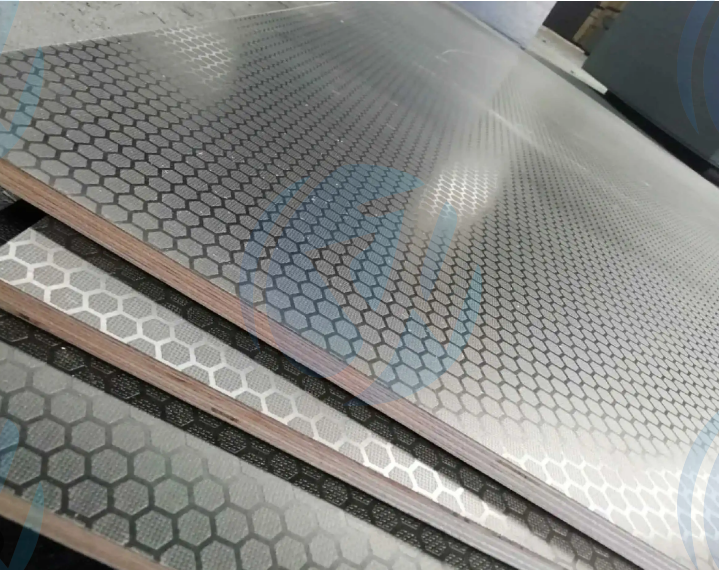

Film types

Black Film

|

Brown Film

|

Red Film

|

Anti Silp Film

|

The film is opaque.It is literally kraft impregnated with melamine glue or phenolic glue. Usually generic brands or taier brand.

It can increase the use of plywood, waterproof and flame retardant effect.

Film color can be black color, brown color, red color or green color. OEM and ODM are also available.

Contact us for free sample

- WhatsApp: +8616506393789

- plywood@yiwanjiawood.com

- Room 1008, Block A, Phase I, Yigao Shanghai Street, Lanshan District, Linyi City, Shandong Province